From Waste to Value: HDPE Blue Drum Recycling Process Explained

Introduction

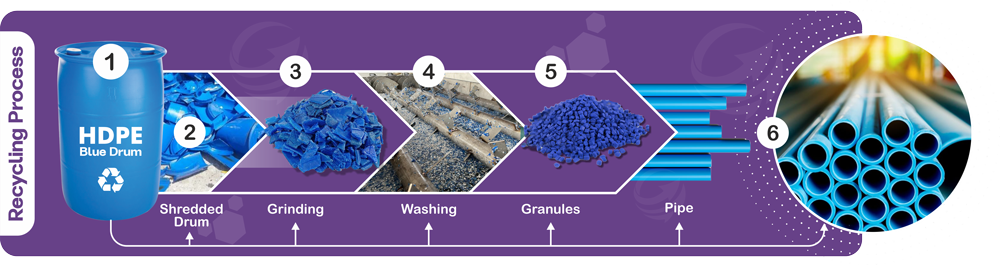

HDPE blue drums, known for their robustness and chemical resistance, are commonly used for storing and transporting liquids, typically with a capacity of 200 liters. Recycling these drums at the end of their life cycle promotes sustainable production practices and reduces environmental impact. This comprehensive guide traces the entire process of converting scrap HDPE blue drums into suitable materials for making new products. From collection to reprocessing, which includes shredding, grinding, washing and re-granulating, each stage plays a vital role in sustainable resource management. Our platform, the Scrap Marketplace, facilitates seamless connections between buyers and sellers of various HDPE products, ensuring efficient recycling and use of these valuable materials.

HDPE: What Is It?

The thermoplastic polymer HDPE, or high-density polyethylene, is renowned for having a high strength-to-density ratio. It is frequently utilised in the creation of plastic timber, geomembranes, corrosion-resistant pipes, and bottles. HDPE is a perfect material for a variety of industrial applications because it is non-toxic, resistant to chemicals, and recyclable numerous times.

Can HDPE Drums Be Recycled?

Drums made of HDPE are indeed very recyclable. Mechanical recycling techniques, which entail physical operations like shredding, grinding, washing, drying, and re-granulating, can be used to transform them into new HDPE products.

To see how our application can assist in this process, check out our recycling application.

Why Is HDPE Recycling Vital?

Impact On The Environment:

less plastic garbage ends up in landfills and the ocean.

Resource Conservation:

Reusing pre-existing materials helps conserve natural resources.

Economic Benefit:

Generates revenue for the manufacturing and recycling sectors.

Sustainability:

By converting garbage into useful products, it promotes a circular economy.

Procedure In Detail: From Scrap To New Products

1. Gathering And Arranging

Collection:

Blue HDPE drum barrels are gathered from a variety of sources, such as recycling initiatives, warehouses, and industrial facilities. Collection centres frequently work with companies to effectively collect big amounts of drums.

Sorting:

After being gathered, the drums are categorised according to colour (usually blue) and material composition (HDPE). To guarantee that only materials of the highest calibre move on to the recycling process, sorting can be done manually or using automated technologies.

2. Removing And Shredded

First Cutting:

Industrial saws or cutting equipment are used to cut large HDPE blue drum barrels into smaller, easier-to-manage pieces. This stage makes handling and additional processing easy.

Shredding:

The chopped material is fed into powerful industrial shredders. The drums are broken down by these machines into uniformly sized smaller bits, or flakes. Shredding is essential because it increases surface area and decreases material size, preparing the material for next processing steps.

3. A machine For Grinding Granulators:

A granulator is used to refine the HDPE fragments that have been shredded. The material is ground into finer flakes or particles by this machine. Particle size homogeneity is ensured by grinding, which makes it easier to clean and treat materials in later stages.

4. The Cleaning Procedure:

The pulverised HDPE flakes are thoroughly cleaned in order to get rid of impurities like residues, adhesives, and labels. The flakes are normally washed in a sequence of tanks with water, detergents, and mechanical agitation.

Modernised Washing Systems:

Flotation tanks are used by some recycling operations for washing. By separating pollutants according to their buoyancy, these tanks improve the cleaning process’s efficacy and efficiency.

Chemicals And Temperature:

Water that has been boiled to between 60 and 80°C (140 and 176°F) is typically used for washing, and mild detergents or caustic soda (sodium hydroxide) may be added to help eliminate lingering impurities.

5. Equipment For Drying:

To get rid of any remaining moisture, cleaned HDPE flakes are dried. For this, air dryers and centrifuges are frequently employed to make sure the flakes are totally dry before processing.

Air-Drying:

Spread out in well-ventilated locations, HDPE flakes can air dry during manual processes or in smaller facilities. While it takes longer, this technique produces dry flakes that are ready for re-granulation.

6. Quality Assurance And Testing

Quality Assurance:

Quality control procedures are used throughout the recycling process to guarantee that the recycled HDPE satisfies predetermined requirements for durability, strength, and purity.

Testing:

Properties like chemical resistance, melt flow index (MFI), and tensile strength are tested on recycled HDPE material samples. MFI is a crucial determinant of the viscosity and flow properties of the material during processing. An MFI of 0.3 is frequently the goal for HDPE, which is used to make pipes.

7. Extruder Machine For Re-granulation:

An extruder machine melts and extrudes the HDPE flakes after they have been dried and cleaned. In order to create uniform strands, the melted plastic is forced through a die after the flakes are heated till they melt. After cooling, these threads are divided into tiny pellets or granules.

By Hand Extrusion:

HDPE can be melted and formed into granules using DIY setups or desktop extruders for small-scale recycling. Manual extrusion is more labor-intensive yet appropriate for amateurs or small enterprises.

How Is HDPE Drum Flakes Extrusion Pelletizing Done?

Pelletizing Via Extrusion:

HDPE flakes that have been cleaned and dried are fed into an extrusion machine in this procedure, where they melt and form into a continuous thread. After cooling, the thread is divided into homogeneous pellets or granules. This is a productive method of transforming HDPE flakes into a shape suitable for a range of industrial uses.

How Can HDPE Be Recycled To Create New Items?

A number of processes, such as collection, sorting, cleaning, and processing into new materials, can be used to recycle HDPE. After that, the recycled HDPE is utilised to create new goods like construction materials, pipelines, containers, and plastic timber.

The HDPE Mechanical Recycling Process For Recycling:

The most popular technique for recycling HDPE involves physical procedures like washing, drying, re-granulating, shredding, and grinding. New goods are made using the HDPE that has been recycled.

The HDPE Recycling Collection Process:

Collect HDPE items from different vendors.

Sorting:

Take HDPE apart from impurities and other plastics.

Cleaning:

Give the HDPE a wash and take off any contaminants.

Processing:

Regranulate, grind, and shred the HDPE.

Manufacturing:

Create new goods using the HDPE that has been recycled.

Producing Original Items

Product Uses:

Regranulated HDPE is adaptable and utilised in many different production processes:

Melting and extruding HDPE granules yields HDPE pipes. Because of its resilience to corrosion and long lifespan, these pipes are utilised in drainage, irrigation, and water supply systems.

Plastic lumber is a weather-resistant and durable material that is used to make outdoor furniture, decking and fencing.

Bottles & Containers:

Made with HDPE’s strength and chemical resistance, these containers are used to package a variety of consumer items.

Building materials are used to make items like panels, boards, and sheets because they are easy to maintain and long-lasting.

Analysis Of Costs And Market Demand

What Suppliers Want In The UK And Indian Markets:

The Indian market and the UK market both want different amounts of HDPE blue drum barrel scrap and regrind. Many people in India want recovered HDPE because it is cheap and people are becoming more concerned about doing things in a way that doesn’t harm the environment. In the UK, strict rules about the environment and the need for high-quality recycled materials are what drive the market.

The demand for HDPE blue drum barrel scrap and regrind varies between the Indian and UK markets. To compare current prices and suppliers, visit our daily price page for more information

Cost Analysis:

The price of collecting, transporting, sorting, processing, and quality controlling HDPE scrap in order to make new goods is affected by a number of factors. In general, it costs less to recycle HDPE in India because of lower operational and labour costs. In the UK, on the other hand, it costs more because of tighter rules and higher operational costs.

Conclusion

A thorough and organised procedure is required to recycle 200-liter HDPE blue drum barrels into new products, starting with collecting and sorting and ending with re-granulation and production. Every stage guarantees the recycled material’s quality and purity, leading to the production of premium, environmentally friendly items in the end. Businesses and people can support resource efficiency and environmental sustainability by comprehending and putting this method into practice, converting waste into useful resources.

Frequently Asked Questions

Ans : Blue drums are typically used for storing and transporting liquids, chemicals, and hazardous materials due to their chemical resistance

Ans : A standard blue drum usually has a capacity of 200 liters.

Ans : Blue barrels typically also have a capacity of 200 liters, similar to blue drums.

Ans : Plastic drums are commonly made from High-Density Polyethylene (HDPE), a durable and versatile plastic resin.

Ans : Similar to blue, white barrels are used for various liquids but are often preferred for food-grade or pharmaceutical applications due to their color-coded cleanliness standards.

Ans : The color is primarily for identification; blue is often used for chemicals and liquids sensitive to light, while black is used for general-purpose applications.